With the improvement of people's living standards, people pay more and more attention to and participate in furniture design when decorating, especially in the negotiation of plans, consumers' demand for personalized, diversified and customized furniture is becoming more and more prominent , Therefore, furniture companies are increasingly investing the proportion of production in customized furniture.

Since the traditional mass production method is difficult to meet the needs of customized furniture with differentiated shapes and sizes, most enterprises are forced to invest more manpower and material resources to complete orders, which is inefficient and expensive. With the maturity of advanced manufacturing technology, many enterprises have begun to change their development concepts, using advanced software to connect with CNC equipment, and forming a flexible plate production line integrating CNC cutting processing center, edge banding machine, and CNC drilling processing center. The software gradually Replacing people as the "brain" of the production line plays an irreplaceable role in the production process and even the order management process, reducing costs while doubling production capacity. This article mainly introduces the "big move" of bill splitting software

1. Definition of bill splitting software

Literally, "splitting orders" is the abbreviation of "splitting orders". The software of splitting orders means that after the production company receives an external order, the design department uses the software to design the product drawings, and the software automatically splits the entire drawing into substrates. , components, specify the order decomposition work required for the production of components at all levels, and connect with the production equipment to complete the various processes of terminal production and packaging.

2. The "big trick" of bill splitting software

Order management: Provide store customer service personnel to place customer orders in the system, fill in the customer's order request information, the system will automatically generate the corresponding production order number and customer order correspondence, and the customer can track the order status in real time later.

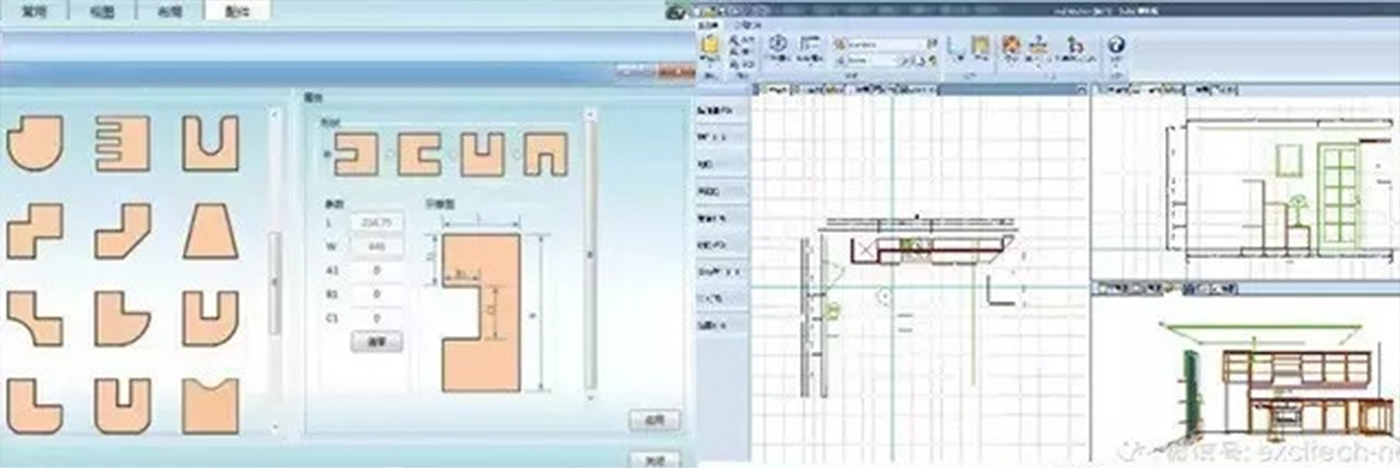

Precise design in the early stage, users can select the model in the material library and then modify the relevant dimensions, or customize the model to generate three-view, three-dimensional renderings, etc.

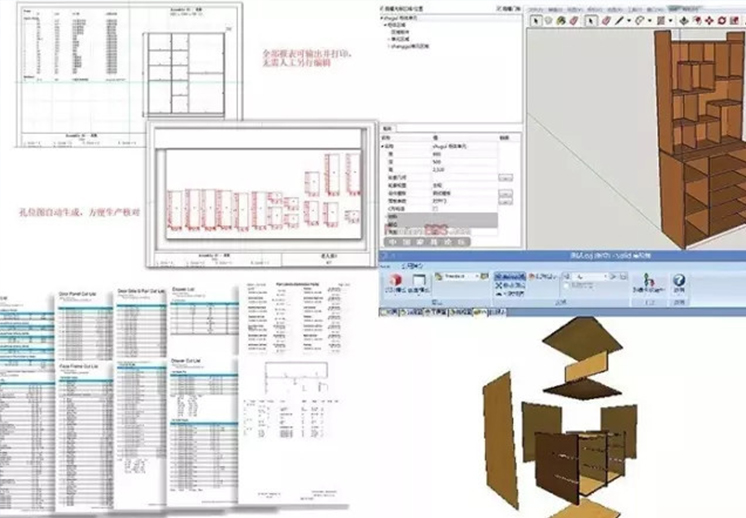

Quickly and accurately disassemble the bill, and the background automatically generates sheet hole map, edge banding, hardware assembly diagram, explosion diagram, bill dismantling list, quotation, material cost list and other information, which has a lower error rate and higher efficiency than manual work.

Automatically optimize typesetting, cut plates in the most reasonable way, and minimize plate waste.

It is connected seamlessly with automation equipment such as electronic cutting saws and CNC drilling machining centers.

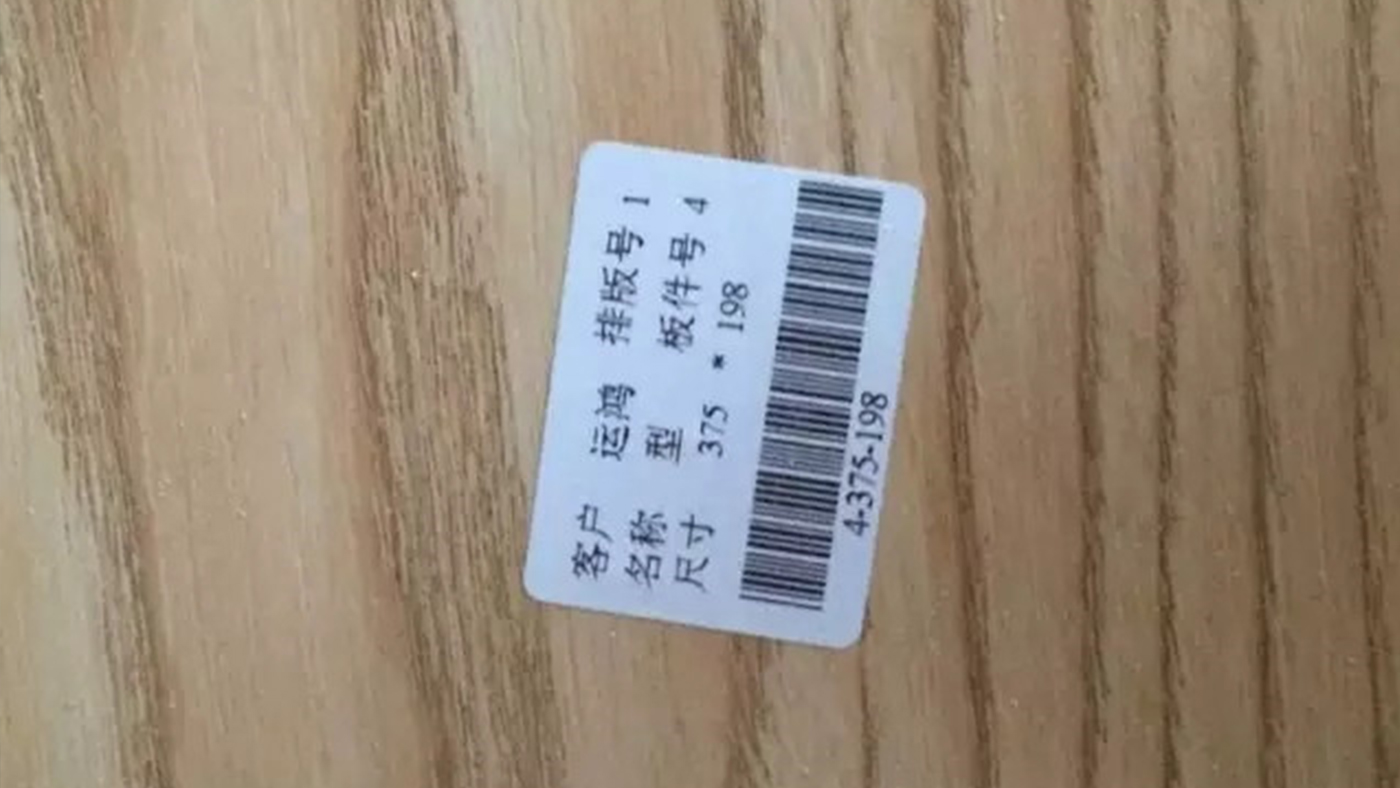

Automatically generate processing barcodes or QR codes, and connect with automated production equipment to realize automatic processing by scanning barcode machines.

The remaining material information is stored in the warehouse and can be retrieved and used in time.

Automatic production of packaging information, docking with the packaging process

The order dismantling software goes deep into each process of production and management, truly realizes precise guidance of production, increases production capacity, reduces dependence on labor, and scientific management. For customized orders, it can realize large-scale production without pressure, and can adapt to enterprises of any size from design From production to production, from store to factory, from front-end to back-end, these are the "big tricks" of bill splitting software, and they cannot be replaced by humans.

3. Commonly used bill splitting software

Well-known bill splitting software abroad include: TopSolid, Cabinet Vision (CV), IMOS, and 2020. These software are very mature in terms of automation and very easy to use. CV has only been sold in the Chinese market in recent years, and foreign big-name equipment manufacturers are all docking with CV. IMOS comes from Europe and is very good at CAM output. At present, the output of German Himile equipment is using IMOS modules. Domestic software includes Yuanfang, Haixun, Sanweijia, etc. Most of the domestic software is packaged or secondary developed based on foreign software.

If you have any specific questions about this information, please feel free to ask!

We are specialized in producing all kinds woodworking machine,cnc six side drilling machine,computer panel saw,nesting cnc router,edge banding machine,table saw,drilling machine,etc.

Tel/whatsapp/wechat:+8615019677504/+8613929919431

Email:zywoodmachine@163.com/vanessa293199@139.com

Post time: Jul-18-2023