The utility model relates to the technical field of labeling machines, in particular to a fast access label storage device for a fully automatic labeling machine.

The fully automatic labeling machine is an automated equipment that integrates feeding and labeling. It is an indispensable front-end equipment for the automation of the woodworking center. Under the current mature automation control, customers have increasingly higher requirements for the reliability, efficiency, and space occupation of fully automatic labeling machines in woodworking centers. In the past, a fully automatic labeling machine was connected to a woodworking center, but now a fully automatic labeling machine needs to be connected to two or even more woodworking center equipment.

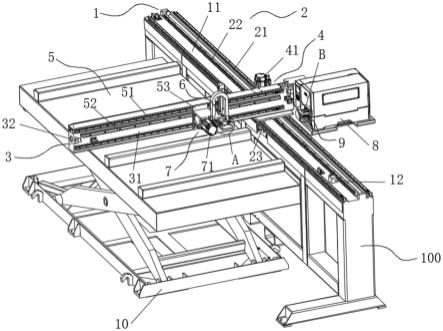

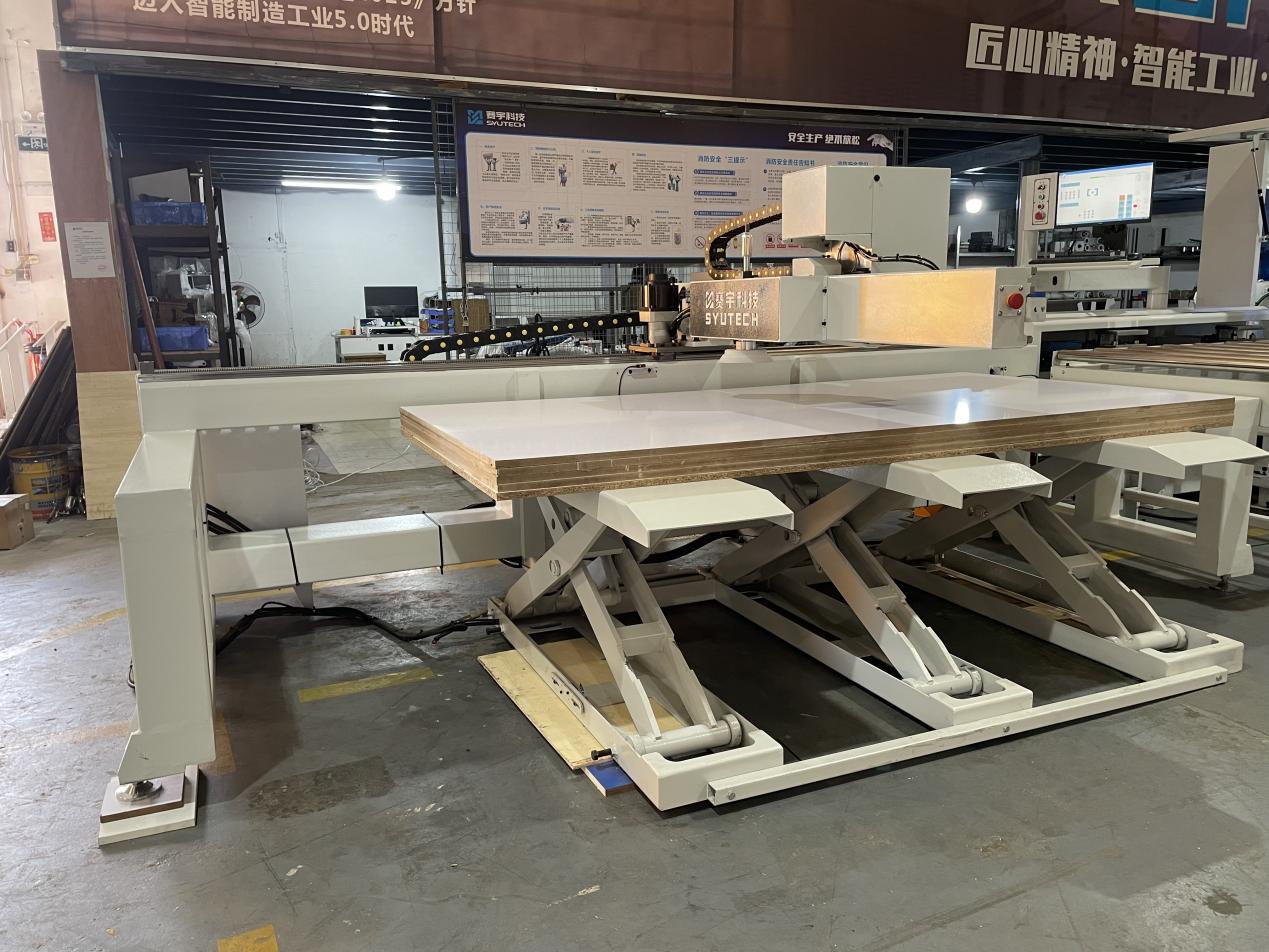

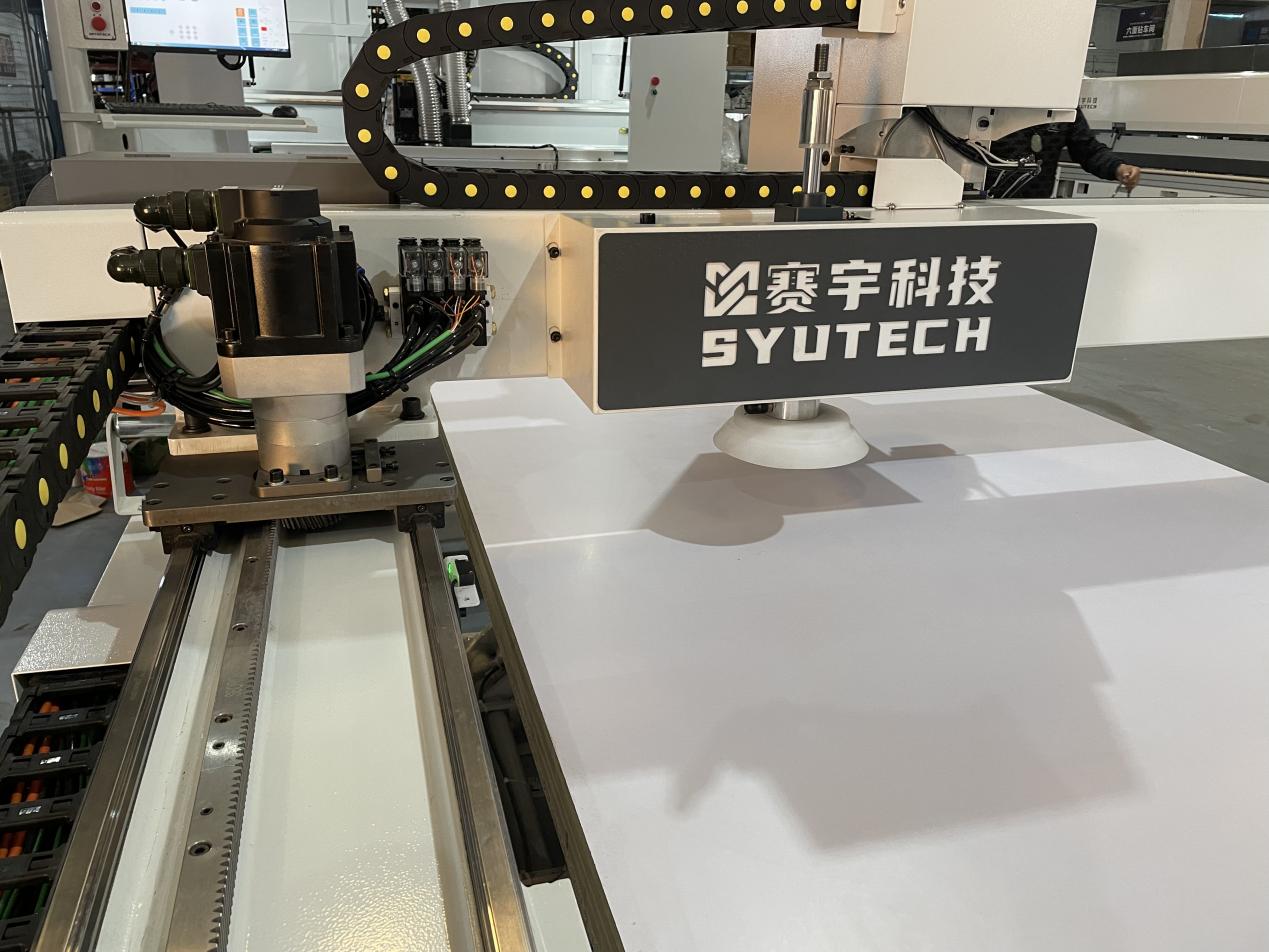

At present, a common method in the industry to improve the efficiency of labeling machines is to synchronously move the labeling head and printer installed on the same fixed plate to the required labeling position along the x-axis and y-axis. The labeling head and printer are fixed on the partition. The label pick-up plate on the labeling head is connected through a cylinder and can be extended to a position near the printer outlet to wait for label printing and then retract to avoid labeling at the target position. interference. However, there are technical problems with the existing technology: In order to improve efficiency and save space, fully automatic labeling machines in the woodworking industry adopt a U-shaped frame base and cantilever beam structure, allowing forklifts to place stacked boards from the side of the machine onto a lifting table. In the existing technology, the labeling head and the printer are installed on the same fixed plate, and the fixed plate moves along the y-axis on the cantilever beam through the guide rail, slide block and driving mechanism. The mainstream printers currently used in labeling machines are large and heavy.

Therefore, the simple structural change of the existing technology, that is, installing the labeling head and the printer on the same fixed plate, inevitably requires a larger load design for the cantilever beam, the fixed plate sliding along the y-axis, and the guide rail. Slider kinematic pair and driving mechanism. Obviously, such a simple structural change does not comply with the economic principles of mechanical design. In the existing technology, the labeling head and the printer are fixed on the partition board. The label pickup plate on the labeling head is connected through a cylinder. The cylinder can be extended to a position near the paper outlet of the printer to wait for the label to be removed. Retracts after printing is completed to avoid interference when labeling at the target location.

This modification adds a cylinder drive action and drive mechanism. Compared with the solution of the present utility model, the unnecessary actions and motion mechanisms added in the control will inevitably increase the failure rate. Obviously, this change does not comply with the principles of economy and reliability in mechanical design.

The working principle of the suction cup grabbing labels in the prior art is that the suction cup moves above the paper outlet. When printing labels, the air blowing device provided below the paper outlet blows upward to keep the label paper flat and attached. to the sucker. After the label paper is printed, the suction cup uses vacuum to suck out the label. This method has high requirements on the air volume, layout position, and blowing angle of the air blowing device. It is inconvenient to adjust, and it is prone to abnormal problems such as label folding, label blowing off, and failure to suck the label.

If you have any specific questions about this information, please feel free to ask!

We are specialized in producing all kinds woodworking machine,cnc six side drilling machine,computer panel saw,nesting cnc router,edge banding machine,table saw,drilling machine,etc.

Tel/whatsapp/wechat:+8615019677504/+8613929919431

Email:zywoodmachine@163.com/vanessa293199@139.com

Post time: Dec-28-2023